At Gen-El-Mec Associates, Inc., we have the ingenuity to undertake geometrically challenging projects and deliver precision quality results.

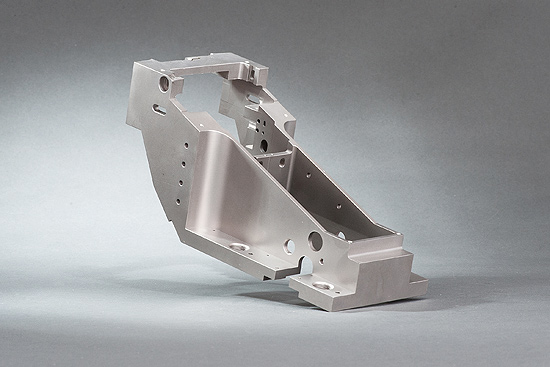

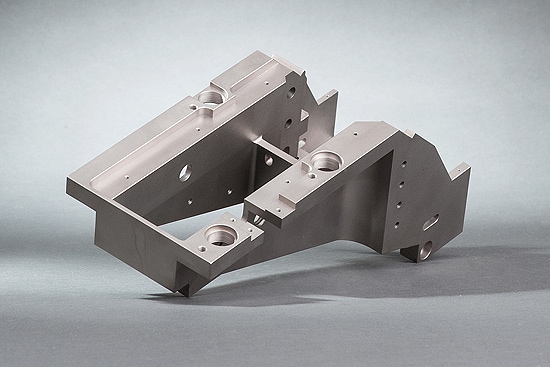

A customer in the semiconductor industry approached us to produce the custom invar housing shown here, a richly detailed part with many difficult to machine features. Material of construction was Invar, an exotic nickel-iron alloy chosen for its outstanding dimensional stability under changing temperature conditions.

Utilizing 5.0″ diameter 6.75″ long bar stock, rigid tooling setups on our vertical CNC machining center enabled us to cleanly cut the surfaces, while accurately aligned and firmly supported drills allowed us to create finely threaded holes as small as M1 x 0.25.

Multiple in-process inspections using precision calibrated CMM equipment validated that we met the ± .010 mm dimensional tolerance requirement of this critical component, which featured dimensions of 69.5 mm in length x 80.9 mm in width x 169.3 mm in height.

For more information about this project, or if you are seeking a precision solution for a critical application, contact us today.