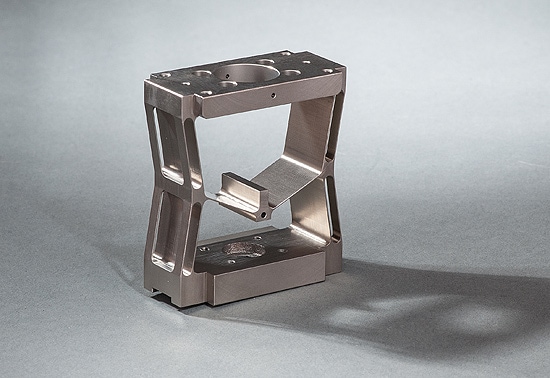

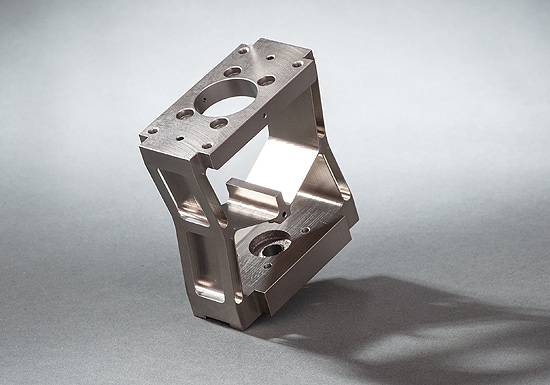

As specialists in complex milling of richly detailed and geometrically accurate components, Gen-El-Mec Associates, Inc. was contracted to manufacture the titanium flexures pictured here for a client in the aerospace industry.

Requirements dictated that the component be conventionally machined –the customer specifically stipulated no EDM. Our manufacturing specialists developed innovative machining strategies to form the component solely on our CNC vertical mill.

Tool paths were devised that would not place excess pressure on the .014″ thin wall sections and enable us to keep within the ±.0005″ tolerance requirement. The finished component, which featured dimensions of 1.25″ in length x 2.25″ in width x 2.5″ in height, was measured on the CMM multiple times during the cycle to confirm its dimensional accuracy.

To learn more about this project, or interested in our manufacturing services, contact us today.